Was Every Packard Vehicle Tested?

This is a question often asked by our visitors.

The answer is yes, but not every Packard was tested at the Packard Proving Grounds after Packard built another testing track just outside of its plant in Detroit.

Below are two news articles that were published in 1932 that describe how Packard Motor Car Company instituted a plan to break in each Twin Six with a 250-mile drive at the Packard Proving Grounds. The vehicle would then be certified by engineers as “ready for any kind of driving on the road”. After its 250-mile run, it would be polished and inspected by engineers. Once the vehicle passed each test and was given approval, the car would be wrapped in a paper bag for delivery. This way, its new owner would have the pleasure of unwrapping their new spotless Packard as if it were one big, wonderful present.

October 11, 1932 – article from The Daily Freeman out of Kingston, New York

June 26, 1932 – article from the Nashville Banner

Most likely, the task of having every car driven up from the plant in Detroit to the Packard Proving Grounds in Utica for such a test proved costly and quite the chore. For these reasons, Packard most likely chose to build another test track just outside their plant in Detroit.

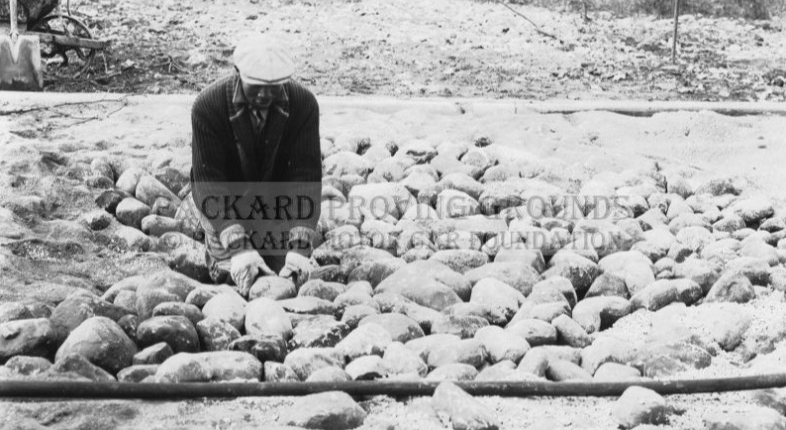

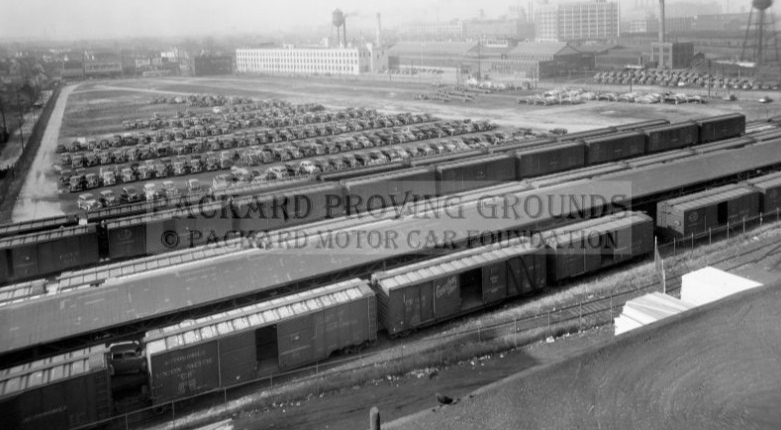

In 1933, Packard built a ten-acre supplementary testing track within its factory gates at Harper and Mount Elliott streets in Detroit. Two concrete tracks, each stretching a half mile, were constructed with the help of the Thomas D. Currie Construction Company. A “prize bed” road of cobblestones, rumble strips, holes, ruts, and humps was also created to test every Packard vehicle’s endurance.

This test track within the Packard plant complex provided the opportunity to give every Packard vehicle a final road test to inspect the car under actual driving conditions. This included a check into the vehicle’s carburetor, steering, shock absorbers, and electrical units. The test provided the chance to make any necessary adjustments before the actual delivery of each car.

As the photographs show, a lot of thought and planning went into the construction of the track to ensure that every vehicle underwent rigorous testing. The test track’s varied conditions helped evaluate how each vehicle responded to vibration, noise, and speed.

The photograph below shows the test track with the Packard factory visible in the background. It also shows 1933 Packard models speeding along the new course.

By 1959, construction of the I-94 freeway cut in next to Harper Avenue, turning Harper into the service drive that still runs past the old plant site today.